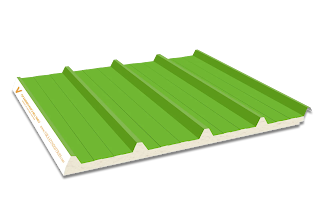

PUF Sandwich Panels have emerged as a preferred choice for modern construction due to their excellent thermal insulation, energy efficiency, and durability. Whether you're building a cold storage facility, an industrial warehouse, or a commercial structure, these panels can significantly enhance the quality and sustainability of your project. However, to maximize their benefits, proper installation is key.

In this blog, we’ll explore some essential tips and best practices to follow when installing PUF sandwich panels.

1. Choose the Right Type of PUF Sandwich Panel

Before you start the installation process, it’s important to select the correct type of PUF sandwich panel for your project. Consider the following factors:

- Core Density: PUF panels come in various core densities, which determine the insulation performance. For colder climates or applications requiring high thermal resistance, choose high-density panels.

- Outer Material: The outer metal layers (usually galvanized steel, aluminum, or stainless steel) vary in terms of thickness and coating. Ensure the material is suited to your environment, considering factors like exposure to corrosive agents.

- Panel Thickness: The thickness of the panel directly affects its insulating properties and strength. Choose a thickness that meets both your structural and insulation needs.

2. Plan the Layout and Positioning of Panels

Proper layout and panel positioning are crucial for both functionality and aesthetics. Follow these guidelines:

- Mark Reference Points: Start by marking the reference points for panel installation. These points will ensure that the panels are aligned correctly throughout the process.

- Start from the Bottom: Begin installing the panels from the bottom edge (floor or foundation) and work upwards. This approach ensures proper alignment and prevents the panels from sagging.

- Overlap the Joints: When installing the panels, make sure that the vertical joints overlap correctly. This overlap will prevent air gaps that could reduce the insulation’s effectiveness.

3. Secure Panels Properly

One of the most important steps in the installation process is securing the panels firmly in place to avoid sagging, warping, or separation over time.

- Use Correct Fasteners: Use screws, bolts, or nails that are specifically designed for PUF sandwich panels. The fasteners should be corrosion-resistant and long enough to ensure the panels are securely attached to the frame.

- Space the Fasteners Appropriately: Fasteners should be spaced according to the manufacturer's instructions. Typically, they are placed about 200-300mm apart, but this can vary depending on the thickness and application of the panels.

- Ensure Even Pressure: When fastening the panels, apply even pressure to avoid damaging the metal exterior. This will also ensure that the foam core does not get compressed, which could impact its insulation properties.

4. Seal the Joints Properly

Properly sealing the joints between the panels is essential to maintain the insulating properties and prevent water or air infiltration.

- Use Sealant or Gasket: Apply a high-quality sealant or gasket material at the joints to create a weatherproof barrier. This helps prevent thermal bridging (where heat or cold passes through the joints), which could reduce the panels' overall performance.

- Double-Check for Gaps: Inspect each panel joint for gaps. Even small openings can compromise the effectiveness of the panels, so be sure that each joint is properly sealed.

5. Handle Panels with Care

PUF sandwich panels are durable, but they can be susceptible to damage if not handled carefully during installation.

- Avoid Dropping or Impact: Panels should be lifted carefully and never dropped, as this can damage the metal sheets or compress the foam core. Use proper lifting equipment like forklifts, cranes, or manual lifts depending on the size and weight of the panels.

- Protect the Edges: The edges of the panels are more vulnerable to damage. Use edge protectors or padding when transporting or handling the panels to avoid chipping or dents that could affect their performance.

6. Work in Suitable Weather Conditions

The installation of PUF sandwich panels can be affected by the weather, so it’s essential to choose an appropriate time for the job.

- Avoid Extreme Temperatures: Extremely cold or hot temperatures can impact the curing of the sealants, adhesives, or coatings used during installation. It's ideal to install panels during mild weather conditions.

- Avoid Rainy Conditions: PUF sandwich panels should not be installed during rainy weather. Water exposure can damage the foam core or reduce the effectiveness of the sealants and adhesives.

7. Insulate the Roof and Walls Correctly

When installing PUF sandwich panels for roofing or wall applications, ensure that both surfaces are adequately insulated:

- Roof Installations: For roofing, ensure proper slope to prevent water accumulation. The panels should form a continuous layer with minimal joints to avoid leaks.

- Wall Installations: For walls, ensure that the panels are secured vertically. Be mindful of wind loads, especially in areas with high winds. Adding support brackets or reinforcements where necessary will ensure the structure remains stable.

8. Regular Inspection and Maintenance

Once the installation is complete, it’s essential to inspect the panels regularly to ensure they continue to perform well over time.

- Check for Physical Damage: Inspect the panels for any signs of physical damage like dents or cracks. These should be repaired promptly to maintain the integrity of the insulation.

- Monitor Sealant Integrity: Periodically check the joints and seals for any signs of wear or gaps. Reseal any areas as necessary to maintain airtight and watertight protection.

- Cleaning and Maintenance: Keep the outer metal surfaces clean from dirt, dust, or debris that could impact the panel's performance or aesthetics.

Conclusion

The proper installation of PUF sandwich panels is essential to ensure their effectiveness in providing thermal insulation, energy efficiency, and durability. By following these tips and best practices—choosing the right materials, handling the panels with care, sealing joints effectively, and ensuring proper alignment—you can maximize the benefits of these versatile panels for your construction project.

Remember that while installing PUF sandwich panels may seem straightforward, attention to detail and precision are key. Investing time and effort into proper installation will result in long-lasting, energy-efficient, and aesthetically pleasing structures.

Comments

Post a Comment